Amazon Replenishment Codes: How to Solve Issues With Your Catalog/Inventory Report

One of the frustrating aspects of running an ecommerce store as an Amazon vendor is when you check your inventory report and see a significant difference between what you were expecting and what Amazon actually ordered. If orders are way down for a specific product or range of products, you need to figure out why before you continue to lose sales.

One reason could have to do with the “replenishment codes” in your catalog. If you see concerning signs in your inventory report, you should match it up to your catalog to diagnose the issue. This guide breaks down how to do that.

Related article: Amazon Vendor Central Download Catalog Guide

Understanding Amazon Vendor Central Replenishment Codes

Replenishment codes are attached to each of your products and tell Amazon what the status of the product is so it can determine whether to order them and how to order them. There are many different codes, and you should understand what each of them means.

Here is the Amazon glossary of terms you will find within Amazon Vendor Central:

AL: Allocated. These products are only ordered manually.

BR: Basic Replenishment. These products must be reordered manually.

IS and OS: In Season and Off Season. These codes refer to seasonal products.

LR: Limited Replenishment. Amazon will only reorder this product as the need arises.

NP: New Product. Products that have recently be listed will receive this code.

NR: Non-Replenishable. These products are not available.

NS: Dropship. Products labeled as NS are fulfilled by third-party suppliers, and are not located in Amazon warehouses.

OB: Obsolete. If a product has this code, it indicates to Amazon that the product is no longer available, and therefore it should not be ordered.

OP: Out of Print. This is a product that the manufacturer no longer produces.

PR: Planned Replenishment. This is the standard code for vendors to apply to items that they are selling to Amazon. It sets your product to be reordered automatically by Amazon.

UN: Unknown. The product's status is unknown.

Related article: How to Use Amazon Vendor Central Reports: A Guide

Why Amazon Vendor Replenishment Codes Are Important

If you’re noticing low inventory or low sales for a product, replenishment codes could be the culprit. For example, if a product is marked OB for obsolete or NR for non-replenishable and you didn’t realize that, sales of the product will plunge because your catalog is telling Amazon not to order the product.

Soft and Hard Rejects

If this is happening to you, there are a few possible reasons. One of them is that if you don’t confirm purchase orders (POs) for a specific item, it could result in the wrong replenishment code and even a suspension of ordering.

For example, if you do a soft or hard reject of purchase orders you receive from Amazon, this can cause a suspension. A soft reject is when you get a PO and indicate a product is temporarily unavailable. Doing this five times will temporarily suspend ordering of this product. If you do a hard reject when you get a PO by indicating that a product is permanently unavailable, product ordering will be suspended after just two instances. If this happens, you will need to submit a support ticket.

Other Common Inventory/Catalog Problems Due to Replenishment Codes

The big problem to be concerned about is when a replenishment code flips from PR, where Amazon is automatically ordering the product, to OB, where Amazon stops ordering it. To prevent this, you should check your products regularly for OB codes and verify that those products are correctly categorized.

New products are also a common problem, as Amazon tends to be less aggressive when it comes to ordering these items. After the first order of this product has been received by Amazon, it should switch to PR. Until this happens, you will not get orders for products that have this code. So if the product is stuck on this code, you will need to check the status of that first order (or see if any product has been ordered at all).

How to Better Monitor Your Inventory Data

Monitoring this data isn’t easy because Amazon doesn’t make it easy. To get inventory data, you have to manually download daily reports for each product and then stitch them together yourself. This is very time-consuming and difficult for ecommerce companies, which is why many of them rely on third-party methods to access this data.

We have put together a free whitepaper that examines each of these methods and helps you identify which is the best option for your business. It is available for a free download below.

READ MORE:

Turn Amazon Data into a strategic Asset

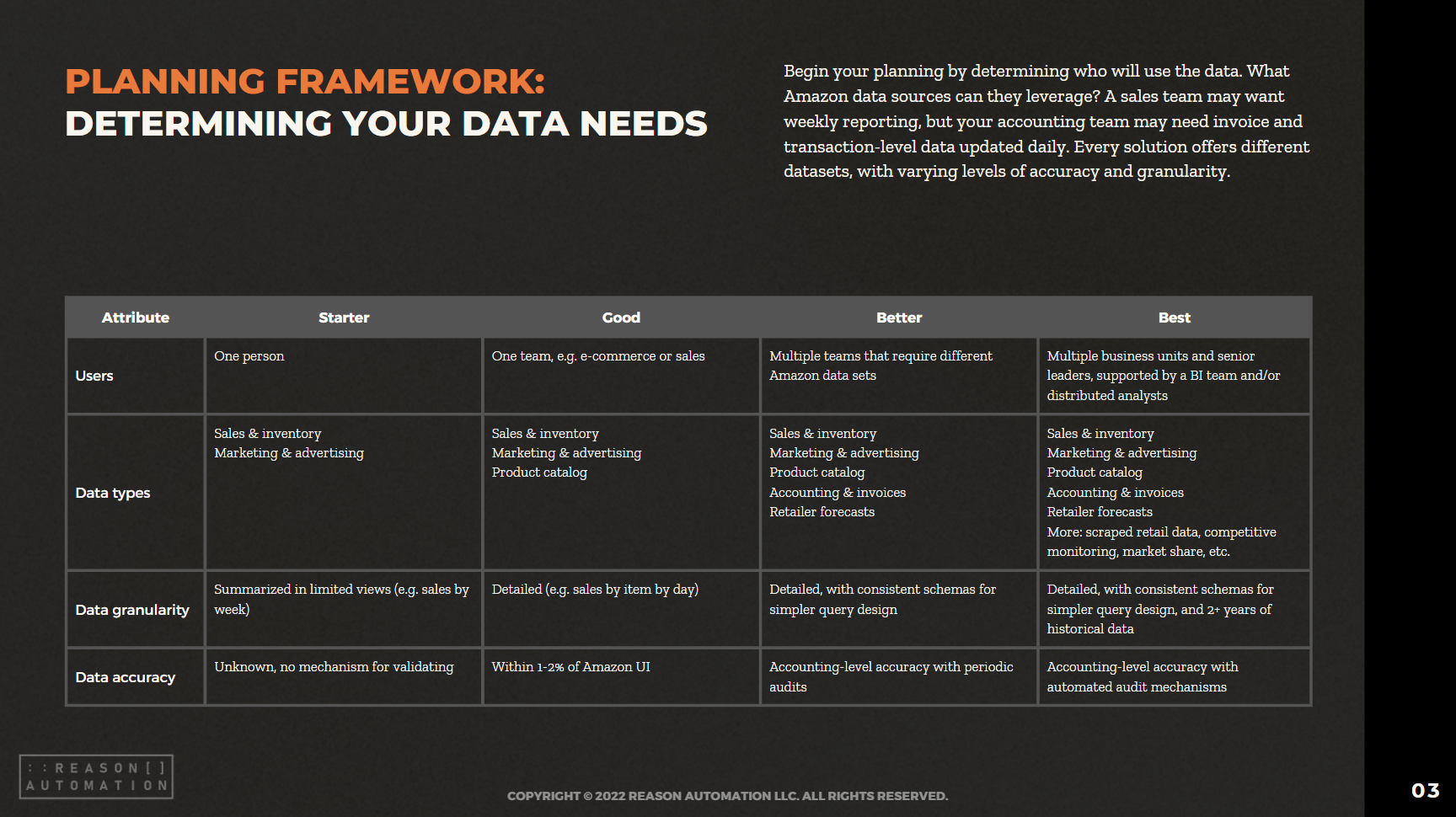

The breadth of Amazon sales, marketing, and supply chain data lets brands find patterns and insights to optimize their Amazon business and other e-commerce channels. But only if you have a plan for extracting the data from Amazon systems, storing it, and preparing it for analysis.

This guide will help you take ownership of your Amazon data—by preparing your business for a data-driven future, and analyzing the most common methods for extraction, automation, storage, and management.